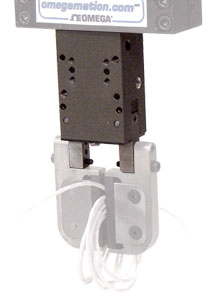

DCT-RE Series Angular 180° Gripper with Spring Assist

Pneumatic Angular Grippers 180°

€1 217,00

DCT-12M-RE

-

Highly Configurable Modular Automation— Exclusive Direct Connect™ Robohand Technology Provides Multiple Mounting Options

-

Full Jaw Opening (180°) Allows Part to be Direct Fed into Gripper, Eliminating One Additional Motion

-

Fail Safe Operation-Internal Spring to Maintain Gripper Force if Gripper Looses Air Pressure

-

Compact Design for Use in Confined Spaces

-

Shielding to Repel Chips for Use in Harsh Environments

-

Precission Gripper - Repeatability ±0.05 mm and Accuracy of ±0.07 mm

-

Up to 5 Million Cycles in Typical Applications and 10 Million with Maintenance

-

Temperature Rating from -35 to 80°C

-

System Requires 4 to 7 bar Dry Filtered (40 Microns or Better) Air Supply

-

Accessory Equipment Required – 4-Way 2-Position Pneumatic Control Valve

Mouvement - Voir Les Produits Associés

Déscription

Find how a pneumatic gripper works on this link.

DCT-RE Series Pneumatic Grippers are angular grippers with a spring assist. This Fail Safe spring allows the gripper to retain the component should the air pressure supply fail, it also allows the gripper to be used with a single acting mode. DCT-RE pneumatic grippers have a 180° jaw opening allowing complete release of a directly fed part. Gripper forces ranges from 40 N to 141 N. These angular grippers are compact and designed for confined spaces, but consideration must be given to allow for the additional space required for the rotating jaws. The adjustable stop accessory (BR) will help to reduce the space requirement by restricting the open position. Standard mounting is from the top, but the gripper can also be mounted from the back of the body and will operate in any direction. Each jaw has a useful rotational stroke of 90° for a full 180° opening and there is a over-stroke of approximately 1.5° before reaching the fully gripped position. Jaws have to be designed to close for a grip of 0° gripping position (parallel jaws).

Harsh Environments are no problem for this gripper due to the shielding that repels chips and other particulate from the internal drive mechanism.

Note: To limit shocks at the end of the opening or closing stroke, it is highly recommended to design jaws with minimal inertia (as light and short as possible). Flow control valves make it possible to reduce the rotation speed and are highly recommended.

Pnuematoc linear motion automation components are double acting air cylinders that require a dry air supply with filtering to 40 microns or better. For best control of pneumatic components, flow control valves (regulating out) should be installed to regulate the speed of the device. Position sensors can easily be added to motion components to detect the end of travel positions of the slides, they are the standard method of communication with the PLC and are available in inductive or magneto resistive sensing styles and come in both PNP or NPN sourcing signals.

Pnuematic Specifications:

Pressure Operating Range: 4 to 7 bar

Cylinder Type: Double acting

Dynamic Seals: Internally lubricated Buna-N

Air Quality Requirements:

Air Filtration: 40 Micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

Maintenance:

Expected Life Normal Application: 5 million cycles w/preventative maintenance 10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

* Addition of lubrication will greatly increase service life.

|

DCT-12M-RE |

DCT-16M-RE |

DCT-20M-RE |

Total Rated Grip Force, F @ 7 bar, L = 25 mm @ 0° |

40 N |

87 N |

141 N |

Stroke |

90° of stroke for each finger |

Weight |

0.12 Kg |

0.20 Kg |

0.33 Kg |

Pressure Range |

4 to 7 bar |

Cylinder Bore Ø |

12 mm |

16 mm |

20 mm |

Displacement |

1.92 cm3 |

4.12 cm3 |

7.92 cm3 |

Temp. Range: Standard Seals |

-35 to 80°C |

Temp. Range: FKM Seals |

-30 to 150°C |

Actuation Open/Close |

0.08/0.05 sec |

0.15/0.12 sec |

0.20/0.14 sec |

Accuracy |

±0.07 mm |

±0.08 mm |

Repeatability |

±0.05 mm |

Valve Required to Actuate Single Acting |

3-way, 2-position |

Valve Required to Actuate Double Acting |

4-way, 2-position |

Fermer

Fermer